BESPOKE PACKAGING SOLUTIONS:

A COMPREHENSIVE APPROACH

In a world where diverse products traverse the global supply chain daily, the need for tailor-made packaging solutions is imperative. No one understands this better than the team here at Rowlinson Packaging Ltd. Operating out of Nantwich, Cheshire since 1966, we have seamlessly blended tradition with technology, employing cutting-edge Solidworks CAD software to craft packaging solutions that align perfectly with your unique requirements.

Crafting Your Perfect Bespoke Packaging

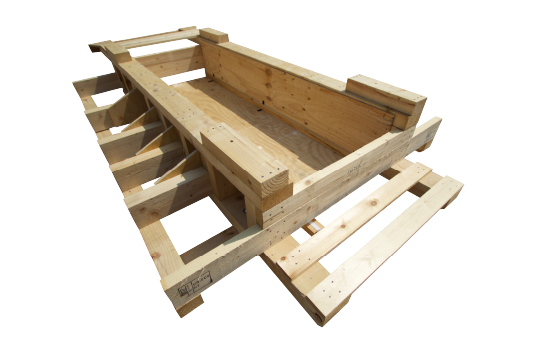

Our commitment at Rowlinson Packaging is to simplify packing operations, optimise shipping volume, and safeguard delicate products during transit or storage. Each customer’s journey begins with our skilled engineers leveraging their extensive experience in creating bespoke packaging solutions. Using your precise dimensions and material preferences, our team meticulously constructs a 3D model within our Solidworks CAD system. This ensures a granular level of control, minimising material wastage, and facilitating cost-effective, time-saving production.

Our Solidworks CAD system enables us to incorporate extras such as specific locking mechanisms or padding tailored to your product’s exact specifications. Once the design is finalised, a sample is generated for your approval, guaranteeing the functionality and readiness for mass production of your bespoke packaging.

Advantages Of Bespoke Packaging

Why should you opt for bespoke packaging for your products? The advantages are manifold. Our seasoned designers, adept at factoring in logistics and cost considerations, produce robust, enduring packaging while maintaining cost efficiency. All our bespoke wooden packaging boxes comply with ISPM15 standards, having undergone heat treatment to prevent infestation during transport, ensuring longevity for multiple journeys.

For instances of damage or wear, our in-house repair service offers a cost-effective solution, ensuring your wooden boxes are promptly restored without additional expenses or production delays. Once the agreed-upon design is manufactured, our streamlined automated process accelerates production, guaranteeing timely delivery of your bespoke packaging solutions. For high-volume requirements, we offer secure storage in our facility, ready for dispatch upon your request.

Order Enquiry

FAQs